A critical factor in next-generation energy storage systems is that all-solid-state lithium-metal batteries are expected to provide better safety and higher energy density than traditional lithium batteries which contain liquid materials inside which can be unsafe, flammable and hard to recycle. The significant difference in all-solid-state lithium-metal batteries is the solid electrolytes which replace the gel-like electrolytes.

Among the potential solid electrolytes, oxide ceramic electrolytes are the more promising, because they have high ionic conductivity, a wide electrochemical window and high chemical stability. However, conventional methods in sintering oxide ceramic electrolytes often require high temperatures (>1100 °C) and long processing times (>10 h), factors which often lead to the generation of impurities and the inability to achieve stable and sufficient interfacial contact between the solid electrolytes and the electrodes.

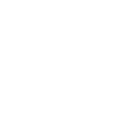

Recently, SPST Liu Wei's group has developed a microwave-induced ultrafast sintering technique that can be used to fabricate a variety of ceramic electrolytes. This technique effectively suppresses the volatilization of lithium through the ultrafast sintering process, and can achieve the integration of electrode and electrolyte in one step by ultrafast simultaneous co-sintering. With this technique, all-solid-state lithium-metal batteries with a high areal capacity are successfully produced with good electrochemical performance at room temperature. The technique developed by Liu Wei’s group provides a new time-saving and energy-saving path for the processing of ceramic electrolytes and all-solid-state batteries. The work was published in Advanced Materials on May 28.

Schematic of the microwave-induced ultrafast sintering technique

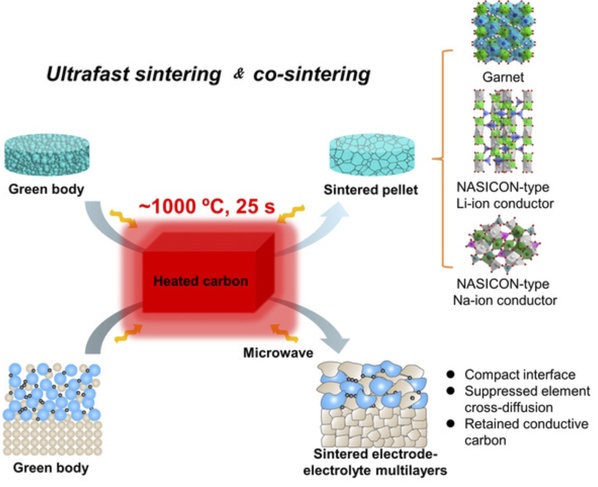

In addition to the sintering technique in solid-state lithium batteries, the poor interfacial contact between the electrode and the solid-state electrolytes is also an urgent problem that needs improvement. Especially in the case of cathodes with high active material loading, the interfacial contact between the electrode and the solid electrolytes is often insufficient. To solve this problem, Liu Wei's group developed a new strategy where the electrodes with vertically aligned channels are prepared by the ice-templating method. They also used an in situ solvent-free UV-curing method to fabricate solid polymer electrolytes that penetrate into the entire electrode. The integration of a low-tortuous electrode and an in-situ-polymerized electrolyte results in high-performance all-solid-state lithium-metal batteries with active mass loaded at about 3 mg/cm2 under room temperature. The work was published in Cell Reports Physical Science on April 20.

For the above two papers, second year Ph.D. candidate Chen Shaojie, and third year Ph.D. candidate Nie Lu are the co-first authors. Assistant Professor Liu Wei is the corresponding author, and ShanghaiTech is the only affiliated institution.

Schematic illustrating the combination of different types of electrodes and solid electrolytes

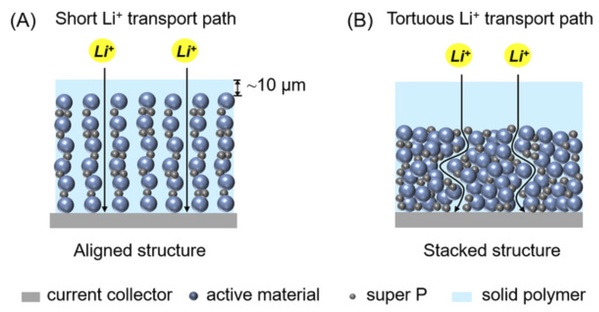

Composite solid electrolytes are generally composed of polymers, inorganic ceramics and lithium salts, which combine the advantages of polymer electrolytes and inorganic ceramic electrolytes and have better properties. Currently, the most studied polymer-based composite solid electrolytes are easily ignited and can be penetrated by lithium dendrites, leading to potential safety problems. Liu Wei's group demonstrated that ceramic-based composite solid electrolytes exhibit better thermal stability and mechanical properties than polymer-based composite solid electrolytes.

The researchers prepared a composite solid electrolyte having the ceramic content between 90%-98%, studied the change law of its ionic conductivity, and systematically analyzed the lithium ion conduction mechanism in the composite solid electrolytes. They found that the ionic conduction mechanism of the composite solid electrolytes with a ceramic content of 90% was closer to that of ceramic electrolytes than to polymer electrolytes. In addition, the researchers simulated the lithium ion transport paths in the high ceramic content composite solid electrolyte and calculated the ionic conductivity of the parallel and vertical ceramic/polymer interfaces, leading to a comprehensive understanding of the properties of ceramic-based composite solid electrolytes, which can provide strategies for the optimization of composite electrolytes in solid-state lithium batteries.

These findings were published in Materials Today Energy. Second year master student Hu Qilin is the first author of the paper.

Diagram of the conduction paths of lithium ion in different solid electrolytes