Recently, SIST Assistant Professor Wu Tao, along with Virginia Tech Professor John Domann, National Chiao Tung University Professor Tien-kan Chung, and UCLA Professor Gregory Carman were invited to write a review paper on strain-mediated magnetoelectric coupling effects. Their paper was published in the MRS BULLETIN journal, with the title ‘Strain-mediated magnetoelectric storage, transmission, and processing: Putting the squeeze on data.’

Magnetoelectric effect is a research field with broad application prospects. As early as 1961, researchers discovered the magnetoelectric effect in chromium oxide. However, the magnetoelectric effect of a single material can only show a small magnetoelectric coupling even at low temperature, which greatly limits the application of this technology. Until 2001, international researchers developed a laminate composite structure composed of piezoelectric and piezomagnetic materials, which showed high magneto-electric coupling at room temperature. This approach is known as strain-mediated magnetoelectric coupling. Subsequent studies have used this mechanism to improve the magnetoelectric coupling more significantly. Strain-mediated magnetoelectric coupling can control the micro-magnetic field by applying voltage, and the laminate composite magneto-electric coupling can greatly improve the magneto-electric coupling. At present, strain-mediated magnetoelectric coupling has become the most effective way to control the micro-magnetic field, and has great application potential in information storage, transmission and processing.

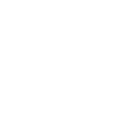

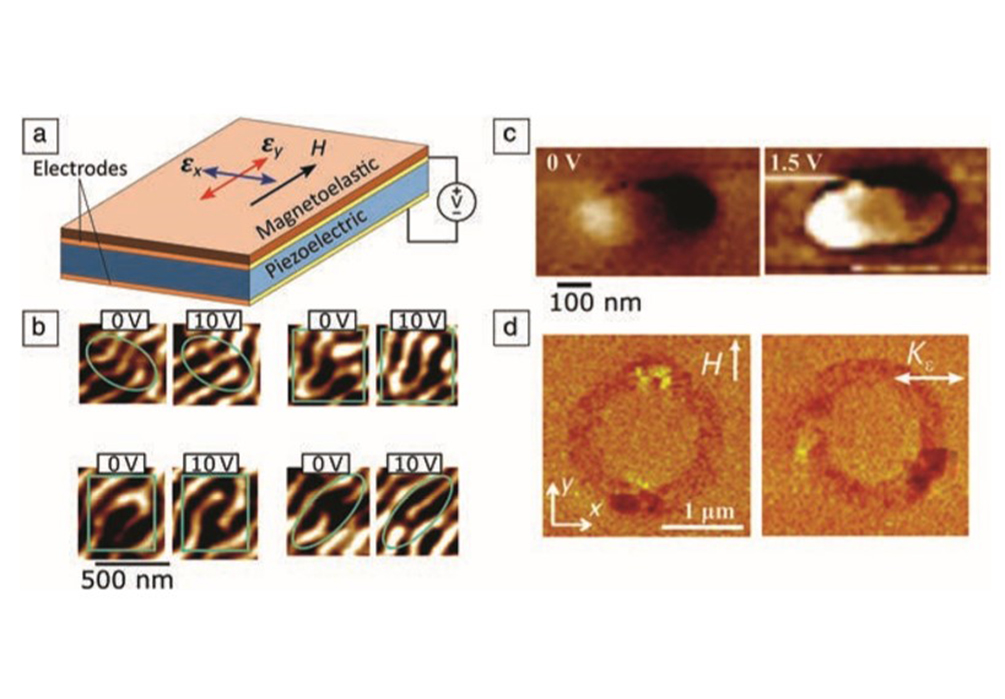

Dr. Wu Tao and his collaborators first reviewed the initial research on large-sized devices and control experiments on magnetic thin films, micro-sized heterojunctions and single domains, and discussed the advantages of this technology in terms of size, speed and energy consumption. They described the application of this technology in information storage, transmission and processing, and introduced three kinds of devices, including memory, antenna and logic unit, giving examples of each. Finally, they explored the future development trends of strain-mediated magneto-electric coupling and its application in antiferromagnetic materials.

Their review also introduces the modeling of magnetic domains under various excitations. For the thin film model, the magnetoelastic energy mainly depends on the biaxial strain, while in the 011 cut PMN-PT, a giant anisotropic hysteresis is found, and a large biaxial stress can be generated. This means that only two electrodes are required to apply uniform biaxial stress over a large area, with two stable states, high transition speeds, and very low energy consumption. The advantages of this technique help to improve important equipment indicators such as energy efficiency, non-volatility, smaller size and faster speed. If in storage, magnetoelectric coupling makes nanosecond switching time possible, and because of its extremely low energy consumption, large-scale use will significantly reduce the global energy consumption in storage.

Strain mediated magnetoelectric coupling technology has developed rapidly over the past 17 years. Studies show how magnetoelectric coupling provides significant energy efficiency improvements for data manipulation tasks, while being faster and smaller than traditional techniques. This technology represents a new paradigm shift in how we store, transmit and process information.

This review covers the important work and research results of Wu Tao and his collaborators in this field. Dr. Wu serves as the second author and this research is supported by the Shanghai Pujiang Program and start-up funding from ShanghaiTech.

Read more at: https://doi.org/10.1557/mrs.2018.260

ShanghaiTech Microsystems and Non-Linear transducers Laboratory: http://small.shanghaitech.edu.cn/

Figure 1. Magnetic domain control of magnetic thin films, single domain rod and rings by applying voltage

Figure 2. (a-e) influence of various energies in the film ellipse (f-g) magnetic domain control using 011 cut PMN-PT (h) applied biaxial stress using two groups of electrodes