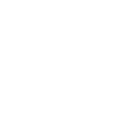

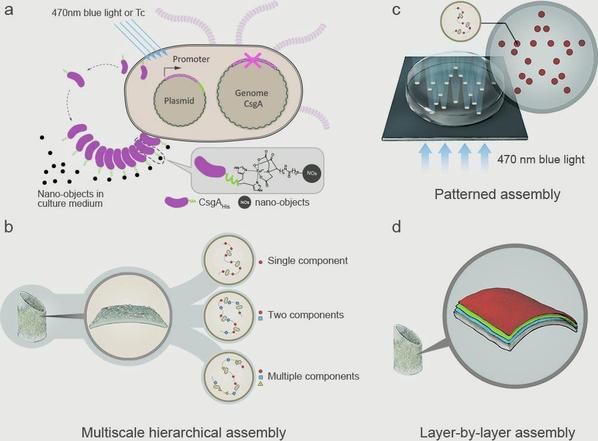

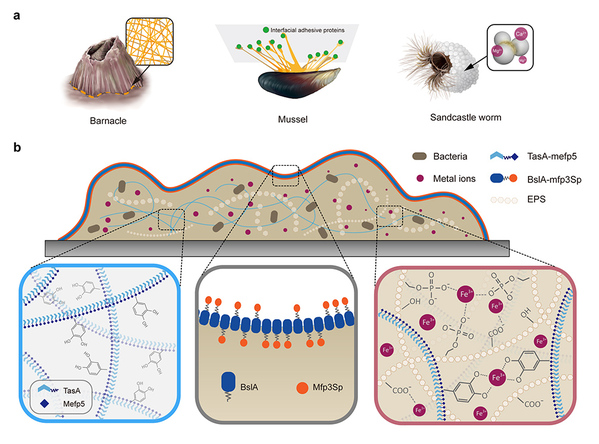

Many natural biological systems—such as biofilms, shells and skeletal tissues—create multifunctional and environmentally responsive multiscale assemblies of living and non-living components. Such living materials grow, self-repair, and adapt to the environment, possessing many living attributes that are unattainable for most artificial materials. Taking inspiration from nature and leveraging the power of synthetic biology, the Zhong group has recently developed living functional materials based on engineered bacteria biofilms. For example, harnessing dynamic E. coli biofilm assembly with light-induced gene circuit, they then designed a cell-based strategy for the templated, spatiotemporally controlled assembly of nanoscale objects in a dynamic, configurable and scalable manner. This research was published in Advanced Materials last year. In addition, they also developed a new type of programmable and printable living materials based on the TasA amyloid machinery of the Bacillus subtilis biofilms which was published in Nature Chemical Biology this year. The engineered biofilms have the viscoelastic behaviors of hydrogels and can be fabricated into diverse microstructures using 3D printing technique. In parallel, this year they published research in Materials Today explaining how by leveraging the engineered biofilm platform, they recently demonstrated the first living cellular glues with tunable adhesion performance and strong environmental tolerance. Their research, at the nexus of synthetic biology and materials science, will provide inspiration for harnessing engineered biological systems to produce smart materials that dynamically respond to their surroundings.

Figure 1. Schematic of the designer cell-enabled strategy for diverse and complex assembly of inorganic NOs in a dynamic, scalable, and hierarchical fashion through programmable dynamic biofilm formation. Advanced Materials 2018, 30, 1705968.

Figure 2. Design for a programmable and printable B. subtilis biofilm production platform. Nature Chemical Biology 2019, 15, 34–41.

Figure 3. Natural underwater adhesion systems inspire biofilm-based functional cellular glues. Materials Today, 2019, DOI: 10.1016/j.mattod.2018.12.039.

Zhong Group

Read more: https://onlinelibrary.wiley.com/doi/10.1002/adma.201705968

https://www.nature.com/articles/s41589-018-0169-2

https://www.sciencedirect.com/science/article/pii/S1369702118309441