Recently, Dr. Ling Shengjie's research group and their collaborators developed an environmentally friendly and scalable “partial dissolution and physical dispersion” strategy to exfoliate silk fibers into different mesostructures. On the basis of the advantages of these mesosilks in tunable sizes, sharp size distributions, high modulus, excellent redispersibility, as well as versatile processability, the applications of these mesosilks in electronic and environmental fields are being further explored, including water treatment, recycling organic solvent, paper sensors, and nanofertilizers. These explorations open a new avenue for silk fiber applications while also providing a pathway to help address critical issues in electronic and environmental fields. Their research results were published in Advanced Functional Materials.

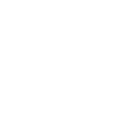

A ubiquitous feature of natural silk fibers is the presence of well-organized mesostructures, including microfibrils, nanofibrils, and nanoparticles. These multiscale mesoconstructions endow the exceptional mechanical properties of natural silks and support physiological functions, such as structural support, defense, and prey capture. However, direct extraction of silk mesobuilding blocks from natural silk fibers remains in its infancy due to the complex hierarchical structure and the high crystallinity of silks. In recent years, a series of “top down” and “bottom up” methods have been developed by Assistant Professor Ling Shengjie and his partners from Fudan University, Zurich Polytechnic, Tufts University and Massachusetts Institute of Technology, to extract and prepare mesoscopic structural units. [Adv. Mater., 2014, 26, 4569; Adv. Mater., 2016, 28, 7783; US patent, WO 2017/192227 Al; Sci. Adv., 2017, 3, e1601939; US patent, WO 2018/081159 Al].

Silk-based materials with diverse size distributions to match various applications.

Isolation of Full-Sized A. pernyi Mesosilks

A. pernyi silks (Figure S1A, Supporting Information) were selected as starting materials, due to their wide availability, low cost, and sustainability (no specific feeding environment is required) when compared with spider and B. mori silks. To isolate mesosilks, the degummed silk fibers were dissolved by 10 wt% NaClO with silk fiber and NaClO weight ratio of 1:1. By modulating and ultrasonic parameters, the full-sized mesosilks were generated, including microfibrils (diameter 1-5μm, length over 100μm), nanofibrils (diameter 13±4 nm,length over 1μm), nanorods (diameter 11±4 nm, length 150-300 nm), and nanoparticles (2-7 nm), and the quantitative relationships between energy input of ultrasonication (for 500 mL 0.2wt% silk fiber/water mixture) were established, along with the diameters of the resultant mesosilks.

Atomic force microscopy (AFM) combined with Derjaguin-Mueller-Toporov mode was employed to evaluate the modulus of the isolated mesosilks. The silk nanorods had an average modulus of 9.8 ± 3.3 GPa, very close to the mechanical modulus of natural single A. pernyi silk (7-9 GPa). In addition, an interestingly “aggregation – dispersion” process by using these mesosilks was strongly regulated by adjusting the pH. As a result, these nanosilk pulps can be collected and stored at 4 °C long term after removing the water through moderate centrifugation.

The downsizing of A. pernyi silk fibers. A) Top-down strategy to extract nanostructures (i.e., nanofibrils, nanorods, and nanoparticles) from A. pernyi silk fibers. B) The map of energy input versus size distribution of A. pernyi silk nanostructures.

Applications of Mesosilks

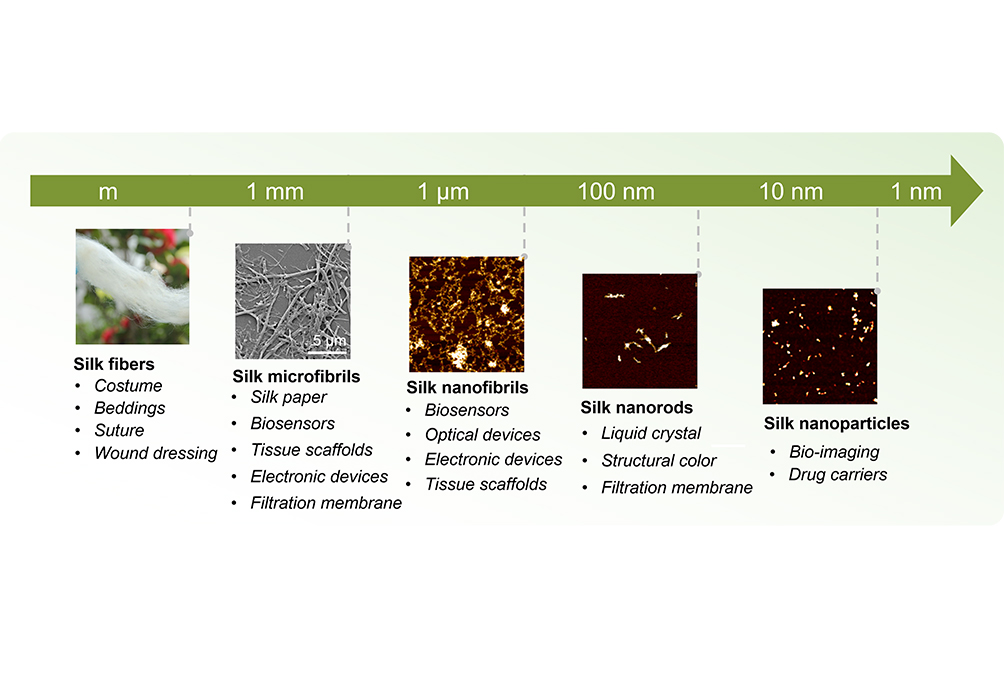

First, silk microfibrils were used for making soft silk paper. After completely air drying, an A4 sized piece of silk paper (210 × 297 mm) with the weight of 5g was formed and appeared flexible and free-standing even without adding any softening agents. Surface SEM images of the silk paper revealed a uniform mesoporous structure with a pore size of 1-3 μm, which matched the size of Escherichia coli (E. coli) bacteria. Therefore, this silk paper can be used directly as a paper-based microfilter to reject bacteria and other microsized contaminants from water. Furthermore, A. pernyi silk nanofibrils are tolerated by most of the solvents, including FA, HFIP, acetone, dimethylsulfoxide, methylbenzene, and chloroform. Accordingly, A. pernyi silk nanofibril ultrafilters were able to remove or recycle pollutants from organic solvents. In addition to microfilters, the silk papers can be functionalized to paper sensors by directly writing conductive patterns on their surfaces.

On the other hand, 11 ± 4 nm A. pernyi silk nanoparticles were utilized to investigate whether silk nanoparticles can help fertilizers enter plants and release nutrients. The distribution of RhB/silk and RhB in bulb slices was further imaged by synchrotron Fourier transform infrared microspectroscopy (S-FTIR), a technique that can provide information on the chemical structure distribution with 5 μm spatial resolution. As with the results observed from the fluorescence microscopy images, the RhB/silk samples had a much stronger infrared absorption of RhB on the inside of the cell walls than the samples incubated in RhB solution. Both results confirmed that the silk nanoparticles facilitated nutrient transport to the cell walls.

The applications of mesosilks. A, B) Photograph of conductive ink patterned circuit board on silk paper and folding silk paper sensor. C-E) Delivering fertilizer into N. pseudonarcissus bulbs using A. pernyi silk nanoparticles.

An environmentally friendly and scalable strategy to extract full-sized A. pernyi mesosilk, including microfibrils, nanofibrils, nanorods, and nanoparticles, was described. Considering the facile, low-cost, and environmentally friendly features, these isolation methods h][ave potential for industrial production. In addition, based on the advantages of these mesosilks with tunable scale, sharp size distributions, high modulus, excellent redispersibility as well as versatile processability, we further explored the applications of these mesosilks in several emerging and critical fields, including water treatment, organic solvent recycling, paper sensors, and nanofertilizers. For silk-based materials, these applications remain in their infancy or have not been previously addressed, such as paper-based filters, organic solvent recycling, and nanofertilizers. Therefore, these exploratory experiments open new avenues for silk applications and provide a possible road to help address critical issues in electronic and environmental fields.

This work was published in Advanced Functional Materials (DOI: 10.1002/adfm.201806380), and supported by Shanghai Pujiang Program (18PJ1408600) and a starting grant from ShanghaiTech University.