Professor Shengjie Ling of School of Physical Science and Technology at ShanghaiTech University, in collaboration with Professor David L. Kaplan of Tufts University and Markus J. Buehler of Massachusetts Institute of Technology published a review article of “Nanofibrils in nature and materials engineering” in Nature Reviews Materials on April 5th.

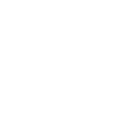

Biopolymer nanofibrils, such as cellulose, chitin, and silk nanofibrils, constitute the basic architectural element of many biological materials that fulfil structural functions. These nanofibrils are composed of different biopolymer molecules, i.e. cellulose, chitin and silk fibroin. However, they usually share common structural characteristics at higher structural levels. For example, they are highly oriented semi-crystalline structures with alternately amorphous and nanocrystalline regions stabilised by hydrogen bonds and van der Waals forces. Their crystal sizes are typically confined to several nanometres. In addition, these biopolymer nanofibrils usually bundle into microfibrils and further organise into fibres and/or higher well-organised 2D- (laminar) and 3D- (helicoidal) structures

These unique nanofibril structures not only endow the exceptional mechanical properties of biological structural materials but also support physiological functions, such as structural support, defence and prey capture. For example, nanoconfinement and nanofibril orientation of spider dragline silk fibre contributes unparalleled mechanical properties, which exhibit a unique combination of high tensile strength (a tensile strength of 1-2 GPa) and extensibility (50-60% strain at failure). These mechanical features enable the silk fibre to absorb a large amount of energy before breaking, resulting in toughness values that are several times that of steel and Kevlar fibres. To adapt against the wind and regulate tree growth, the orientation of laminar cellulose nanofibrils in cell walls makes trees capable of adjusting mechanical properties of the wood according to the functions of different wood tissue types. The 3D helicoidally stacking of chitin nanofibril layers in exoskeletons are able to resist fracture efficiently through energy dissipation and prohibit crack propagation.

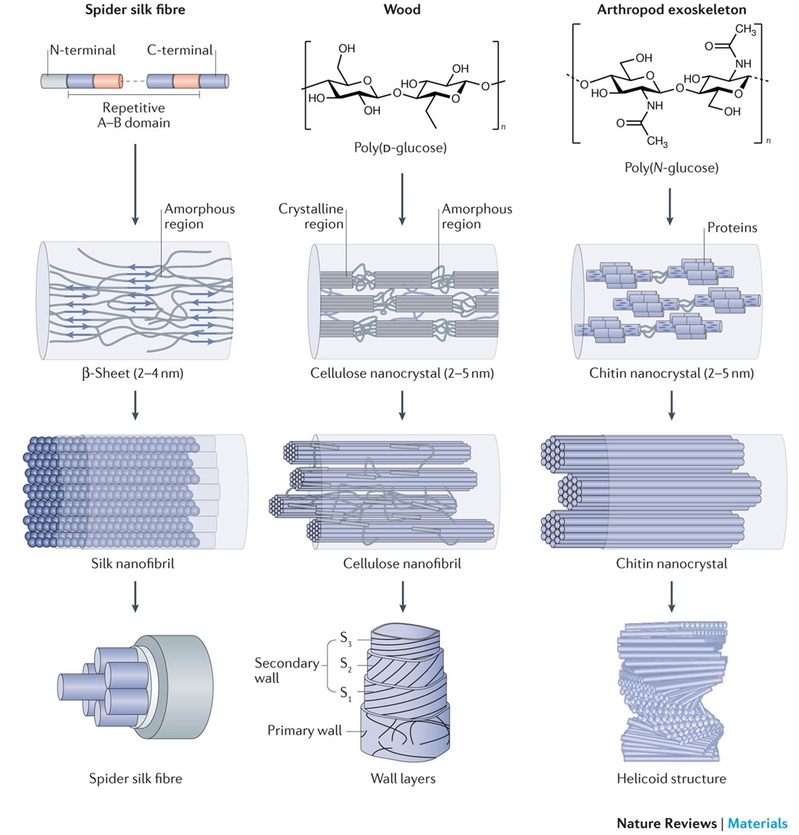

Accordingly, insight into these material strategies in nature offers an opportunity to disclose structure-property-function relationships of natural materials, and to inspire new routes to use these biopolymer nanofibrils. Cellulose, chitin and silk nanofibril, as three of earth’s most abundant biopolymer nanofibrils, have great potential for large-scale applications. In recent years, the applications for these materials have also been widely explored due to their high mechanical performance, sustainability, wide availability, low cost, low weight, and biocompatibility. However, the structures and/or physical properties of the most artificial biopolymer nanofibril-based materials remain inferior to analogues found in nature. Therefore, determining how to efficiently design and use these biopolymer nanofibril-based materials has become an important subject. With the aim of optimising the structural-property-function relationships of biopolymer nanofibril-based materials, a series of studies has recently transferred natural material strategies into artificial biopolymer nanofibril-based material design and process. These studies not only demonstrate the potential success of this approach but also lay out a blueprint for how to design de novo, new features and functions, by building on this approach.

In their review, the authors first introduced several important “universal multiscale construction strategies of nanofibrils” in nature, focusing on strategies utilising biopolymer nanofibrils, including nanoconfinement, nanofibril 2D orientation, and 3D helicoidal stacking. They summarised artificial material design routes for developing biopolymer nanofibril-based materials, focusing on recent work that attempts to mimic the natural structures and then discussed the broader challenges and directions for future developments of these biopolymer nanofibril materials.

This study was supported by a starting grant given by ShanghaiTech University.

Read more: https://www.nature.com/articles/natrevmats201816

Figure 1. Hierarchical structure of silk, cellulose and chitin.

Figure 2. Rational design of nanofibrillar materials.